CORE PRODUCTS

Core products and process packages are applied in various industries, including:

- Leachate management

- Coal and coal chemical industries

- Petroleum and petrochemical industries

- New energy sectors (e.g., lithium iron phosphate, lithium extraction from salt lakes, photovoltaics)

- Steel industry (comprehensive wastewater treatment for steel plants)

- Electricity sector (zero discharge of desulfurization wastewater and cooling sewage from power plants)

- Comprehensive utilization and zero discharge of wastewater in industrial park

Focus on enhancing and transforming:

- Municipal sewage systems

- Food processing wastewater

- Wastewater from livestock farming

Evolved into a “one-stop zero-discharge service provider” for domestic high-salt organic industrial wastewater management.

CORE TECHNOLOGY

Utilize proprietary high-performance membrane separation technology as the primary process package.

Integrate with core technologies:

- OLAND for efficient denitrification

- CRYSTAL for crystal seed softening

- SEVAP for energy-saving evaporation

- ECOR for electrocatalytic oxidation and reduction

Provide solutions for fluoride and silicon removal using various core technologies.

Develop specialized equipment for high-concentration wastewater, including:

- OLAND, SEVAP, UV-AOP, CRYSTAL, ECOR, solidification units, and specialized separation membranes.

Address challenges in wastewater treatment and resource recovery in high-barrier scenarios with elevated organic, salt content, suspended solids, and hardness.

MEET OUR PRODUCTS

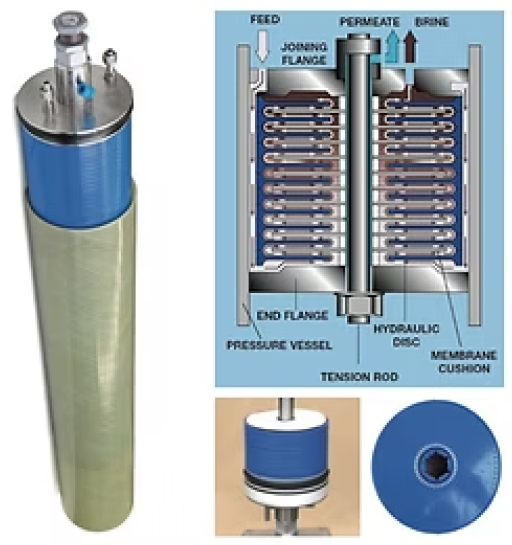

DTRO/NF Disc-tube Membrane Module

- The main components consist of membrane cushions, hydraulic discs, tie-rod, flanges and pressure vessel

- Open channel

- Better hydraulic dynamic design: The fluid flows through the hydraulic disc and forms high speed turbulence on the membrane cushions, which reduces the fouling and scaling potential.

- Using new ultrasonic technology for membrane cushion welding. More uniform welding seam, better rejection rates of salinity and ammonia nitrogen, ensuring the safety and stability of the permeate quality

- Short flow path: 7cmLong service life: up to 3 – 5 years

- High membrane retention rate: up to 99.8%

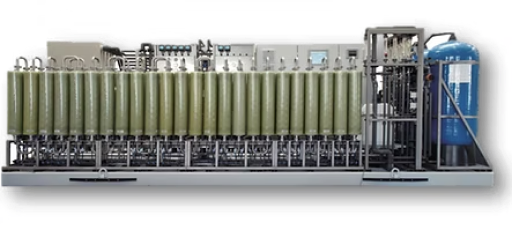

DTRO – DISC TUBE REVERSE OSMOSIS SYSTEM

- DTRO membrane technology offers strong resistance to fouling and scaling, high loading rates, and compact design. Easy to maintain and transport, it can be quickly commissioned in under a week, making it a versatile solution.

- Equipped with DTRO disk tube reverse osmosis membrane technology, the mobile treatment equipment offers outstanding stability, safety, and versatility.

- One of its most notable features is its ability to treat landfill leachate directly without the need for complex pre-treatment equipment. This eliminates the need for additional setup and maintenance, making it an efficient and cost-effective solution for wastewater treatment.

50T/d, 100T/d, 200T/d, 250T/d to 300T/d

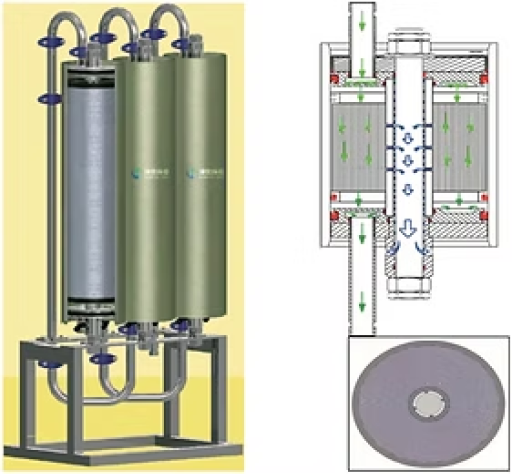

STRO – SPACE TUBE REVERSE OSMOSIS SYSTEM

Main Application Areas:

- Landfill leachate treatment

- Coal mining industry

- Petrochemical industry (PTA)

- Renewable energy industry

- Power industry (FGD, cooling tower blowdown)

- Wastewater from industrial parks

- Electroplating

- PCB industries, etc.

75bar/90bar/120bar

STRO/NF Space-tube Membrane Module

- The main components include membrane envelopes, feed spacer, central tension rod, housing, two end flanges, seals, and connecting boults.

- Open channel

- Adopting anti-telescoping and hydro-dynamic design, the connecting support plate between the centre and the circumference is designed in an arc shape. The disk surface features radial perforations starting from the centre and gradually increasing in size towards the periphery. This design effectively ensures uniform distribution of the influent water.

- Modularized design, compact and flexible

- Long service life: up to 3 – 5 years

- High membrane retention rate: up to 99.8% under standard test condition.

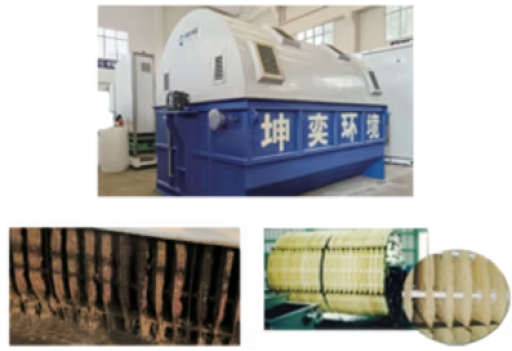

RBC – ROTATING BIOLOGICAL CONTACTOR

- An advance technology for treating wastewater with Bacillus complex bacteria as the dominant microorganism.

- High organic load, high processing efficiency, can effectively remove COD, nitrogen, phosphorus, etc.

- Highly integrated, small footprint, easy to install, and easy to achieve automatic control.

- No additional deodorization treatment device is required, and odour can be effectively removed.

- Less air supply is required, low power consumption and running cost; low carbon-nitrogen ratio. requirement, the minimum operation condition is BOD/TN = 2.5.

- Resistance to acid, alkali and salt contents.

- The system achieve stable operation at low temperature.

SEVAP EVAPORATORS

- Innovative online energy-saving and anti-scaling system

- Include compressor system, cleaning system, dosing system, online anti-scaling system, electric steam heating system, PLC control system, and washing system.

- For wastewater with high organic matter, fouling and scaling problems, no need to stop for frequent cleaning, which greatly improves the production efficiency and reduces energy consumption.

- Treatment capacity; 300-400 tons/day

- Recovery rate DTRO concentration: 80-90%

- Total recovery rate: 90-95%

SOLIDS SOLIDIFICATION TECHNOLOGY

- The mother liquid of the evaporator leachate is high in salts, organics and heavy metal content. Chelating agent is used to prevent leaching of heavy metals, and then thickened by thickener to bind its pollutants, and finally stabilized in the solidified matter.

- The solidified material meets the standard of Table 1 of the “Pollution Control Standard for Domestic Waste Landfills” (GB16889-2008).

- After the evaporation mother liquor is solidified, it is easy to transport, store and dispose.

- Suitable for SEVAP high-efficiency and energy-saving evaporator leachate mother liquor.

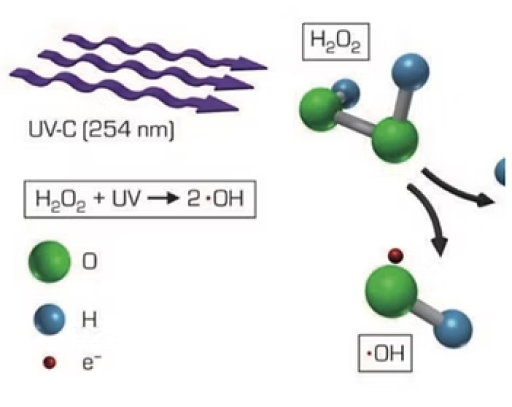

UV-AOP ADVANCE OXIDATION

- Under appropriate wavelengths of light, hydrogen peroxide undergoes photolysis into highly reactive hydroxyl radicals, which rapidly react with organic and inorganic substances in water, producing inorganic byproducts such as water and sulfates.

- It efficiently decomposes organics under standard temperature and pressure facilitating the mineralization breakdown of pollutants, with no selective preference for specific organic contaminants.

- It exhibits high oxidation efficiency, operates automatically, allowing unmanned operation without generating secondary pollutants.

- The reaction conditions are mild, with strong oxidative power, effectively breaking down organic matter into CO2, resulting in high treatment depth.

- Applicable to wastewater with high COD, wastewater with high toxicity, wastewater with high chromatically, and other hazardous wastewater.

CRYSTAL SEED SOFTERNING TECHNOLOGY

- The structure of calcium sulphate seed crystal is the same as the scale, the crystal surface has a large affinity for scale, so the precipitated calcium sulphate molecules in the concentrated solution will be continuously enriched to form precipitates under the action of water

- The calcium sulfate and magnesium sulfate molecules in the concentrate solution will be deposited on the seed crystal preferentially to remove the scale and eliminate scaling.

- High load and large flowrate.

- The removal rate of Ca2+ in water is up to 90%, and the effluent is stable.

- Applicable to RO/NF concentrated brine

EcoN&P DENITRIFICATION PROCESS

The EcoN&P system effectively integrates layered materials to promote microbial growth and facilitate efficient denitrification. This approach is both cost-effective and environmentally friendly, while the addition of thiosulfate accelerates the process and ensures optimal performance in cooler conditions. Together, these components offer a powerful solution for removing nitrate and phosphorus from wastewater.

Utilizing a Structured Mesh:

Our patented PVDC mesh increases the surface area available for bacterial growth, essential for effective wastewater treatment.

Encouraging Bacterial Biofilm Formation:

Thiobacillus and Sulfurovum bacteria form biofilms that break down pollutants, enhancing treatment efficiency.

Minimizing Sludge Production:

This biofilm approach results in lower sludge generation compared to traditional methods, streamlining treatment processes.

Boosting Denitrification with Thiosulfate:

Thiosulfate supplementation improves the denitrification process, especially at lower temperatures.

Integrating with ANAMMOX for Enhanced Efficiency:

The EcoN&P system, when combined with the ANAMMOX process, elevates nitrogen removal rates to as much as 92-95%, making it highly effective in wastewater management.

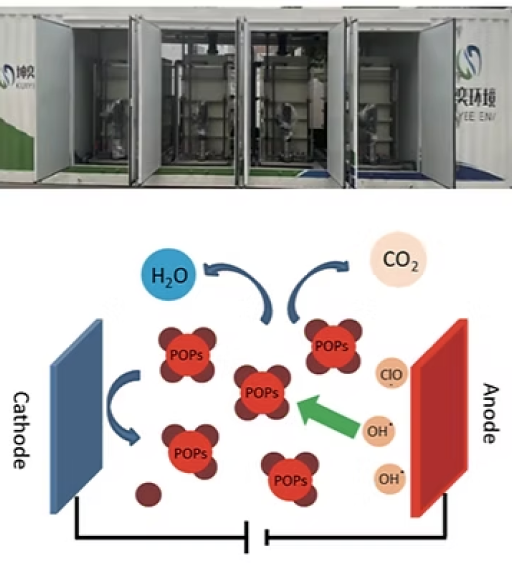

ELECTRO-CATALYTIC OXIDATION REDUCTION

- When the electrode coated with special noble metals is electrified, electro-catalytic oxidation (ECO) and electro-catalytic reduction (ECR) are carried out simultaneously, so that persistent organic pollutants can be effectively degraded and mineralized.

- The system does not need chemicals, does not generate sludge, and can achieve complete discharge without concentrate.

- The equipment has small footprint.

- It has strong de-colouration capabilities, and the produced water is colourless and transparent.

- For water with high nitrate content, ECR with special electrode can reduce it.

- It is suitable for high salinity wastewater. The strong chlorine separation ability products a large amount of hypochlorous acid in the system, making it very effective for ammonia nitrogen removal.

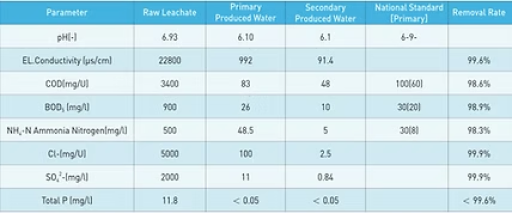

LANDFILL LEACHATE TREATMENT TECHNOLOGY

Landfill leachate is highly polluted wastewater that threatens water resources, exhibiting fluctuations in volume and quality, high pollutant levels, non-biodegradable substances, and nutrient imbalances.

Quality varies with age: the acid phase has a high BOD5 (around 10,000 mg/L) and is suitable for biological treatment, while the methanogenic phase presents challenges due to declining BOD and increased ammonia. Single biological treatments often cannot meet discharge standards, necessitating reverse osmosis technologies, with high-rejection DTRO/STRO membranes effectively removing contaminants.

Containerized leachate treatment systems from Germany offer quick start-up, minimal space requirements, and lower costs while efficiently removing salts and emerging compounds, with flexibility for optional pre-filtration or post-evaporation.