BLUE CHIP CUSTOMER REFERENCES

Leachate Treatment for Waste Incineration Plant

Pre-treatment + Anaerobic UASB + MBR + Tubular Ultrafiltration + DTRO/STRO High Pressure Reverse Osmosis

The anaerobic UASB process removes 75% to 90% of COD from leachate.

The MBR consists of:

- A denitrification tank

- A nitrification tank

- An external ultrafiltration system

The MBR targets ammonium nitrogen and remaining COD.

The biologically pre-treated leachate is directed into the DTRO/STRO reverse osmosis system.

The DTRO/STRO system operates at high pressure, achieving a recovery rate of 80% to 85%.

The produced water consistently meets discharge standards.

Leachate Treatment for Landfill Sites

Pre-treatment + Hydrolysis Tank + MBR + Tubular Ultrafiltration + STRO (DTRO) High Pressure Reverse Osmosis

The hydrolysis process primarily enhances the biodegradability of leachate.

The external MBR system includes:

- A denitrification tank

- A nitrification tank

- An external ultrafiltration system

The MBR system removes ammonium nitrogen with a removal rate of 99% and addresses remaining COD in leachate.

The biologically pre-treated effluent is fed into the reverse osmosis system.

The high-pressure DTRO/STRO membrane system achieves a recovery rate of 80-85%.The produced water consistently meets discharge standards.

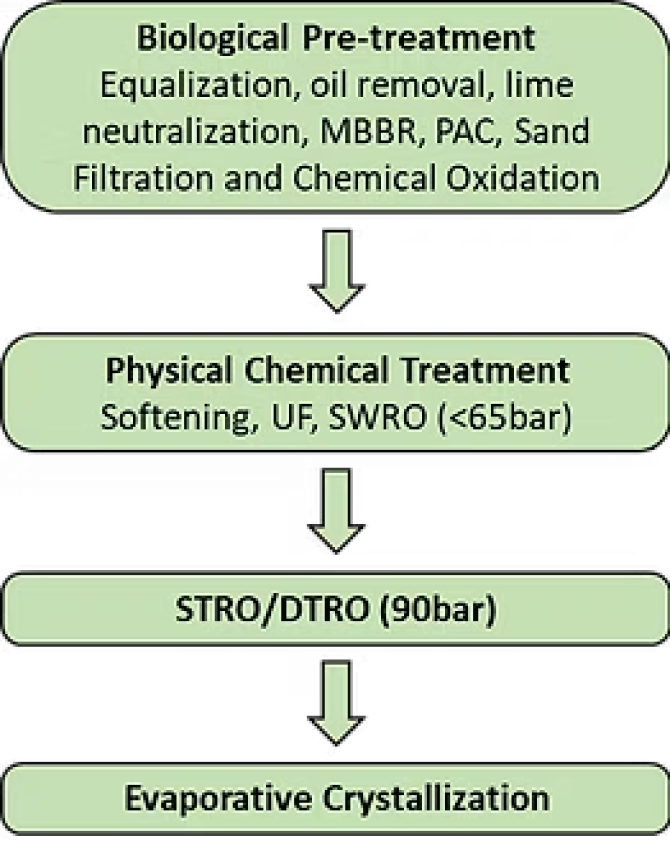

Process of CTX Wastewater Treatment

Technological Advancements:

- Economic viability of converting coal into liquid fuels (gasoline, diesel, petrochemical products)

Water Usage in Coal Chemical Industry:

- Significant water consumption for cooling systems and liquefaction gasification processes

- Results in wastewater with complex compositions

Common Contaminants in CTX Wastewater:

- Salts

- Minerals

- Sulphides

- Ammonia

- Oils and fats

- Cyanides

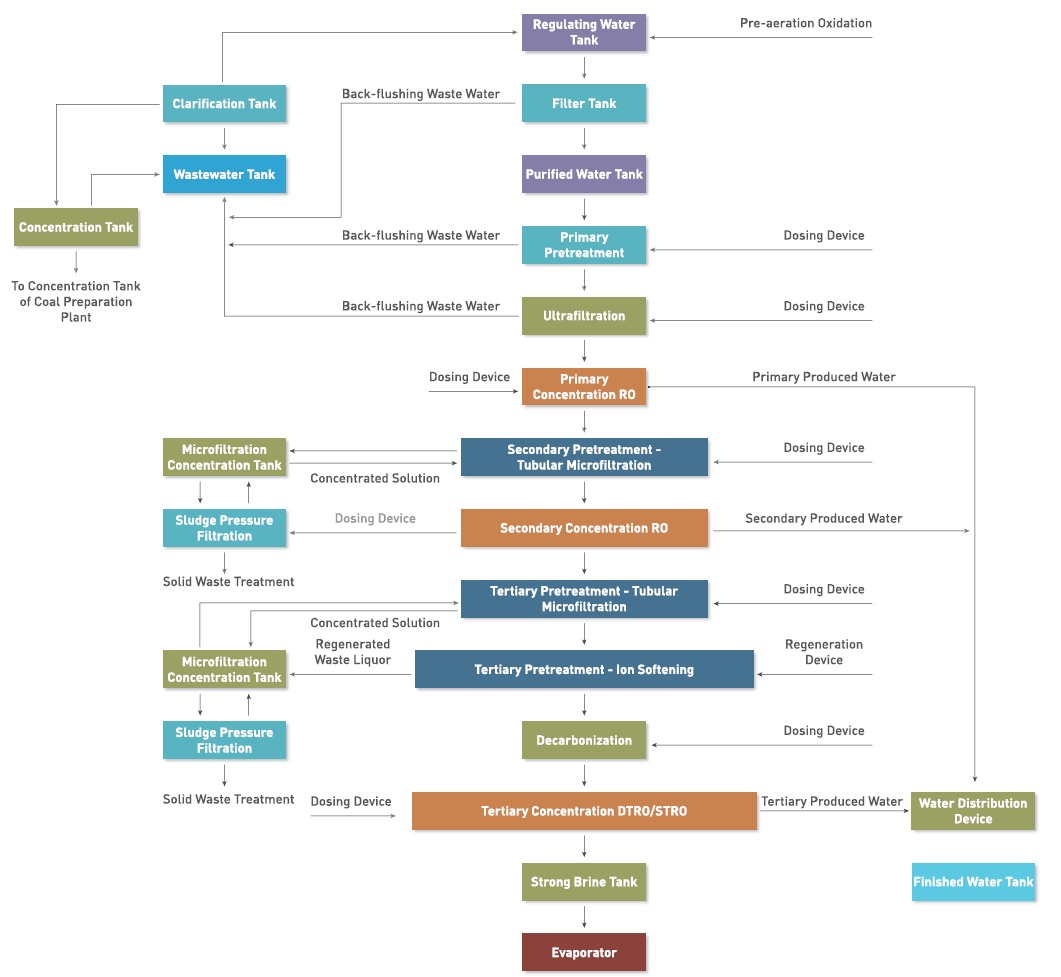

Coal Mine ZLD Project

Ultrafiltration, Primary Reverse Osmosis, Softening, Secondary RO, High-pressure DTRO, Evaporation/Crystallization.

- Project: Coal Mine ZLD (Zero Liquid Discharge) industrial mining wastewater treatment plant

- Capacity: 20,000 m³/day

Treatment Process:

- Ultrafiltration (UF)

- Primary Reverse Osmosis (RO) filtration

- Softening process

- Secondary RO filtration

- High-pressure DTRO technology

- Evaporation/crystallization

Membrane Concentration Stage:

- Salt content increased from 5,000 mg/L to 136,000 mg/L

- Concentration factor: 30

- Water Recovery Rate: 97%

- Reclaimed Water Quality: Meets reuse standards for power plant operations

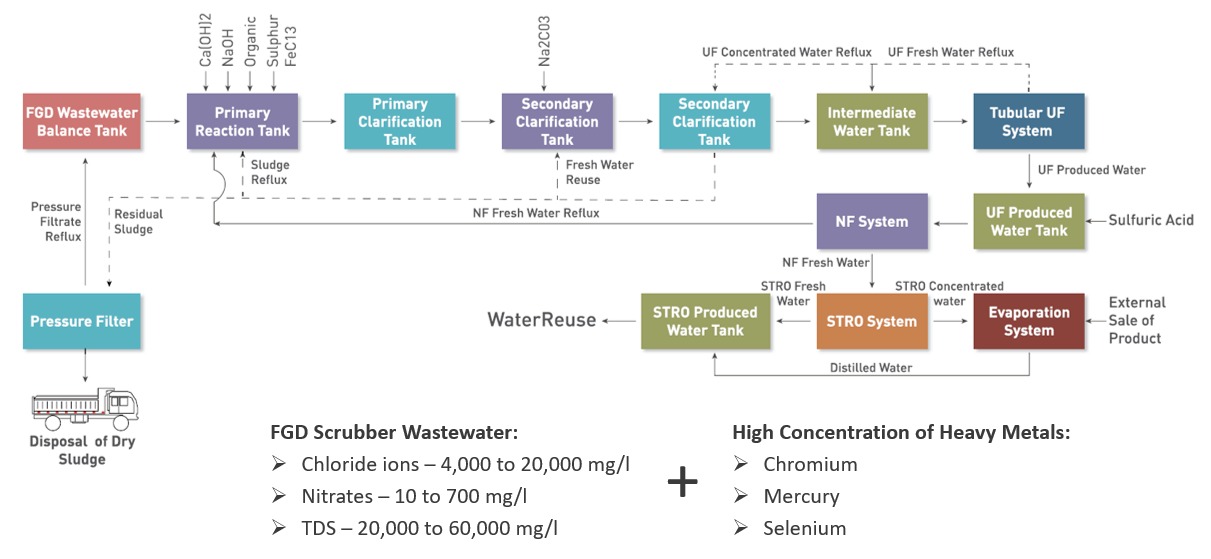

Process of STRO/DTRO for

Wet FGD (flue-gas Desulfurization) Wastewater Treatment

Process Water Treatment Plant for beverage

Ultrafiltration + Activated Carbon Filter + UV disinfection + Reverse Osmosis

- Upgrade existing Process water treatment plants in beverage production sites.

- Provided design, equipment procurement, assembly, installation and commissioning services

- Delivered solutions with 13 trains of 75m3/h treatment capacity for process water

- Adhere to EHEDG specification

- More than 96% increase in water efficiency, re-using process water as cooling and boiler water and reducing product water by 15%

- Additional reduction of operating cost and energy consumption

- Efficient delivery of a full turn-key solutions in 20 weeks

Leachate treatment of domestic landfill in Spain

- Processing scale: 2000 m³/ day

- Treatment process: secondary STRO+ resin adsorption

- Influent mass: conductance >50000µS/cm; COD>10000mg/L, ammonia nitrogen >5000mg/L, alkalinity >9800mg/L

- Production water quality: COD<20mg/L, ammonia nitrogen <5mg/L

Iron and Steel making Plant’s South Blast Furnace Gas Desalting and

Washing Tower Concentrate

Iron and Steel making Plant’s South Blast Furnace Gas Desalting and Washing Tower Concentrate

- Treatment Scale: 250 m³/day

- Treatment Process:

- Tubular ultrafiltration membrane

- Primary DTRO membrane

- Secondary roll RO membrane

- Problem Addressed:

- High COD (Chemical Oxygen Demand)

- High ammonia nitrogen

- High total salt content

- Solution: Wastewater resource recycling of concentrated water from the blast furnace gas desalting washing tower in the steel industry